A tremie is a watertight pipe, usually of about 250 mm inside diameter (150 to 300 mm), with a conical hopper at its upper end above the water level. It may have a loose plug or a valve at the bottom end. A tremie is used to pour concrete underwater in a way that avoids washout of cement from the mix due to turbulent water contact with the concrete while it is flowing. This produces a more reliable strength of the product. Common applications include the following.

- Caissons, which are the foundations of bridges, among other things, that span bodies of water.

- Pilings.

- Monitoring wells. Builders use tremie methods for materials other than concrete, and for industries other than construction. For example, bentonite slurries for monitoring wells are often emplaced via tremie pipe.

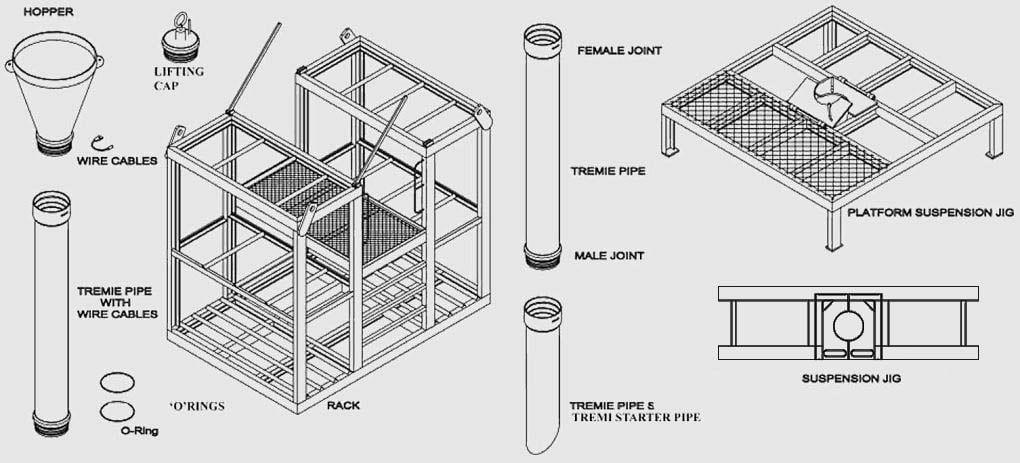

Tremie Racks ready for delivery

Concrete Placement

Three issues are critical to the placement of concrete under water or slurry:

• A delivery method must be used that keeps the concrete separated from the water or slurry and prevents intermixing.

• The concrete must maintain a high slump to completely fill the shaft and flow easily around the reinforcing steel.

• The top of the shaft must be thoroughly flushed at completion of the pour.

Delivery

Concrete placed underwater or slurry must be placed through a closed, sealed tremie or with a pump. A tremie is a smooth steel pipe, usually 10 to 12 in diameter, with a hopper on top into which concrete is deposited. Concrete is discharged out the bottom of the tremie pipe. At the start of the pour, some means must separate the concrete from the water or slurry. Most commonly, the open tremie is inserted to the bottom of the excavation and allowed to fill with water or slurry. A foam rubber plug, usually referred to as a “pig,” is placed in the top of the tremie pipe before the hopper is filled with concrete. As concrete enters the tremie pipe, the pig slides down, separating the concrete from the water or slurry. Once the tremie pipe and hopper is full of concrete, lifting the tremie slightly allows the pig to be expelled, and concrete begins flowing into the shaft. Concrete with the correct slump will often flow up the tremie a considerable distance (10 to 20 feet) while the hopper is recharged as needed. Once flow slows or stops, the tremie is lifted to restart the flow. It is critically important that the tremie remains well embedded in the concrete. Five feet of embedment should be maintained as a minimum at all times. The inspector should check this using a weighted tape to determine the level of concrete within the shaft and then calculating tremie embedment based on the measured length of the tremie.

Failure to maintain tremie embedment will trap the soil cuttings sediment, and washed-out concrete in the shaft. In a correct pour, these materials remain on top of the concrete and are flushed off at the top of the shaft at the end of the pour. Pumped concrete is placed in a similar manner. The concrete and water must be prevented from mixing at the start of the pour, and a foam rubber plug is often used in the pump line as a separator. Additionally, embedment of the pump line into the concrete is critical throughout the pour.

Small Temie Rack

We also have been referenced in Wikipedia regarding tremies which can be found here