In aboveground floating roof storage tanks for fuel & oil, etc., there must be a method of removing rainwater from the dynamic roof. W.E. Couplings Ltd design and manufacture a range of systems for this purpose, from economical flexible rubber hose systems, to long-lifetime stainless articulated pipework systems. We have supplied these systems to storage tank builders and tank farm maintenance teams worldwide for over a decade, and continue to offer a fast and reliable turnaround on a quality range of drain systems.

Applications:

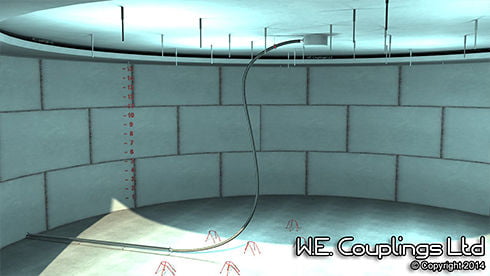

Flexible hose assemblies for immersion inside storage tanks to drain rainwater from the floating roof. Specially compounded covers are used to resist immersion in high aromatic or corrosive liquids.

Lining:

Smooth bore, mandrel built, Nitrile (NBR) or Viton® (FKM) lined hose, depending on the type of hose specified or required

Reinforcement:

Textile cord reinforcement with a high tensile stainless alloy wire helix,

to resist collapsing by external pressure when fully immersed

Pressure:

Although these hoses are rainwater drains experiencing low pressures

when in use, the integrity of the hose assemblies is checked, after

ballasting, by testing to 10 bar with water and vacuum testing to -0.85 bar.

Full and detailed test and material certificates are supplied as a standard.

Covering:

Smooth wrapped finish in the following materials:

PVC/NBR Nitrile Aromatic content up to 80%

Viton® Aromatic content up to 100%

(Tolerance to hazardous environments high in hydrocarbon content)

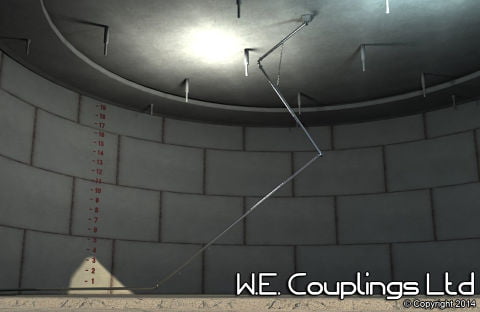

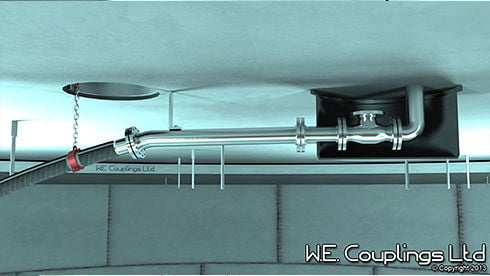

Lead ballast and branding:

Each hose assembly incorporates a permanently attached lead covered stainless steel cable to give the hose a close-to-neutral bouyancy in the stored product. This ensures that even a small amount of rainwater brings the bouyancy of the hose system to negative, triggering the outflow of rainwater. It then returns to floating underneath the ceiling – away from the potential damage area that the ends of the roof legs present. A longitudinal white stripe is permanently branded on the cover of each hose to ensure correct alignment. All hoses are supplied electrically continuous. Clamps and chains with a quick-link for an attachment to the ceiling are also supplied.

Flanges:

Generally mild steel nipples with fixed ASA150 R/F flanges are supplied. Other flanged drillings and material types are available, including swivel flanges. The ballast is permanently attached internally to the top fitting.

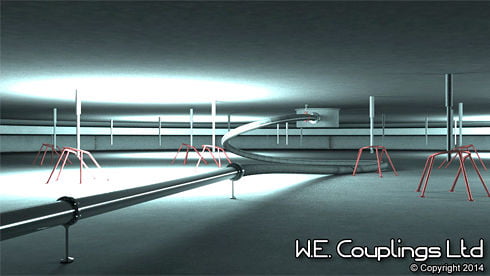

We also design and manufacture our own versions of the traditional articulated system, that incorporate greater lateral stability and fold flatter than other designs, to allow the roof to get lower and therefore potentially save many barrels of expensive Jet fuel, or whatever fluid is being stored in the tank.