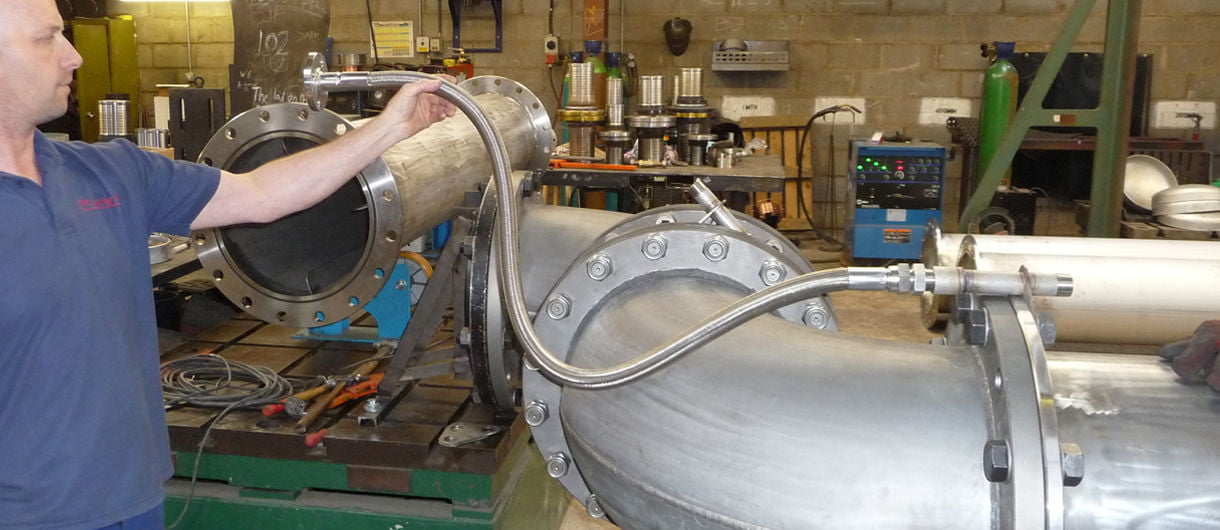

Another of W.E. Couplings’ specialities is high quality Hose Tails, in most cases available immediately as weld ready ends, swivel ring and flanged. Tails are available in a range of material including Aluminium, Carbon Steel, Duplex/Super Duplex steel and Stainless Steel.

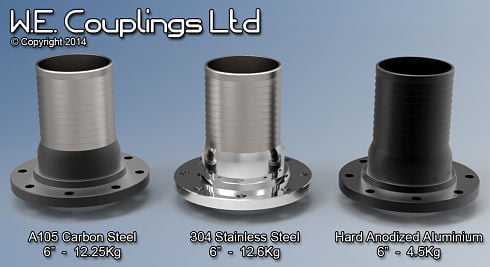

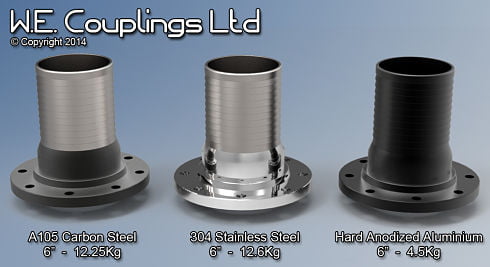

During 2014, W.E. Couplings Ltd has researched and developed a new line of couplings in hard anodized aluminium. This modern material, once it has been subjected to the anodizing process, not only retains the structural strength of it’s steel equivalent, but also offers a huge (around 65%) reduction in weight. Coupled with the sought after non-sparking characteristic of this material, it also performs better than steel under extremes of temperature, from a cryogenic -195°C up to 350°C, thanks to the second phase hardening process. Another important benefit of using hard anodized alloy is it’s corrosion resistance – this material is proven to be effective at resisting corrosion when handling the majority of hydrocarbon type medias, e.g. fuel & oil.

24″ Inch external crimping using our supermax swager

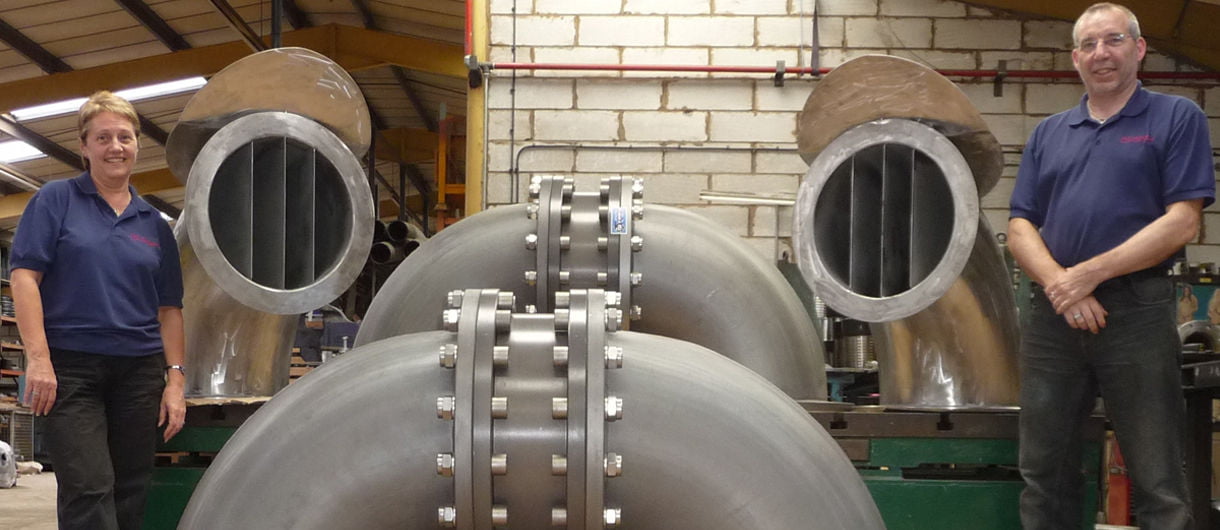

24″ ASA150 Flanged hose tail showing internal bore during crimp

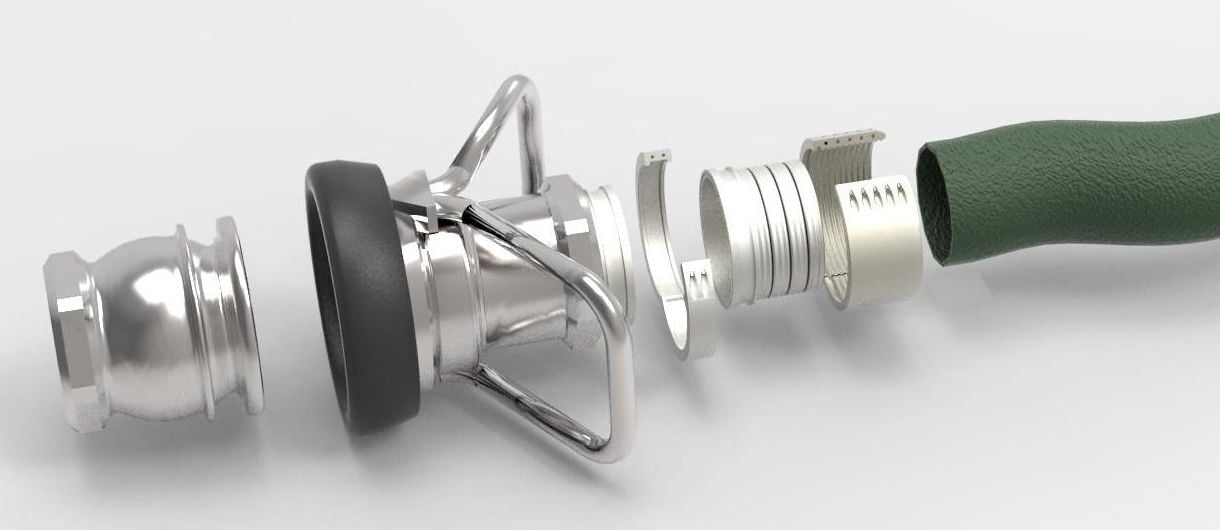

4″ Crimped End showing internal view of tail and ferrule

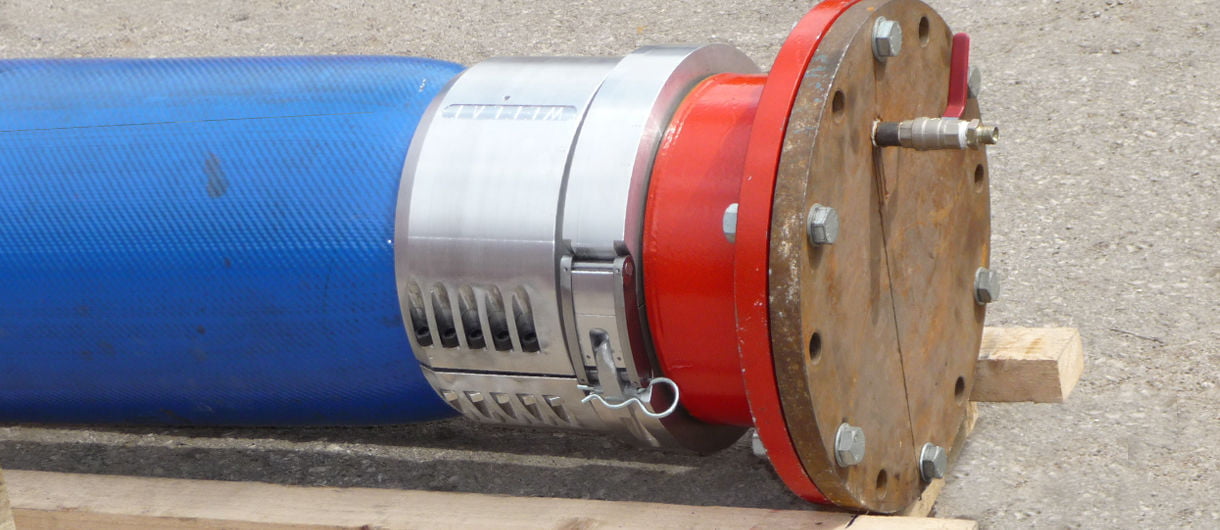

24″ ASA150 Flanged Hose Tail

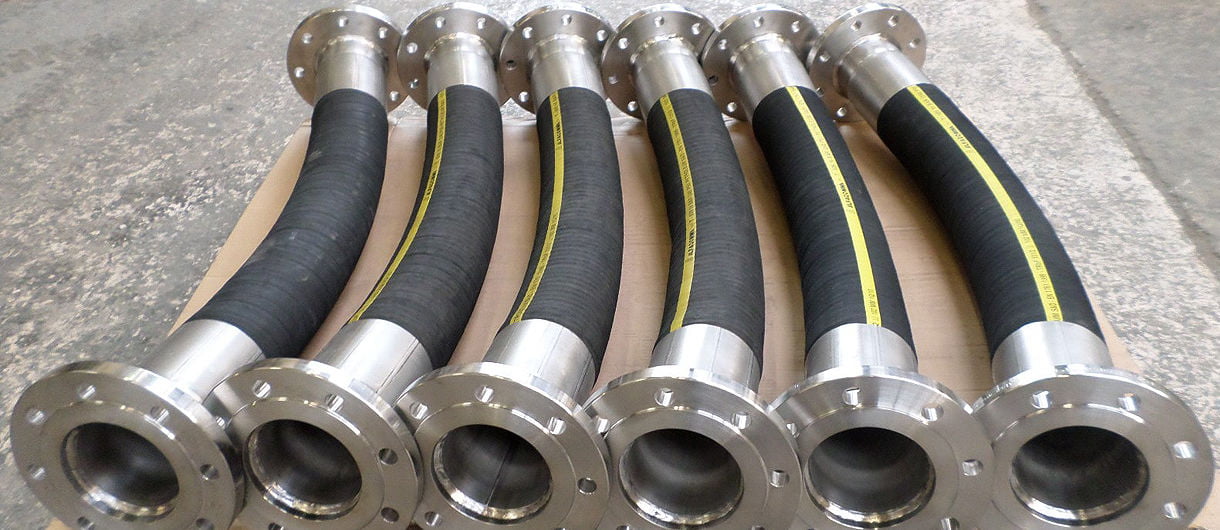

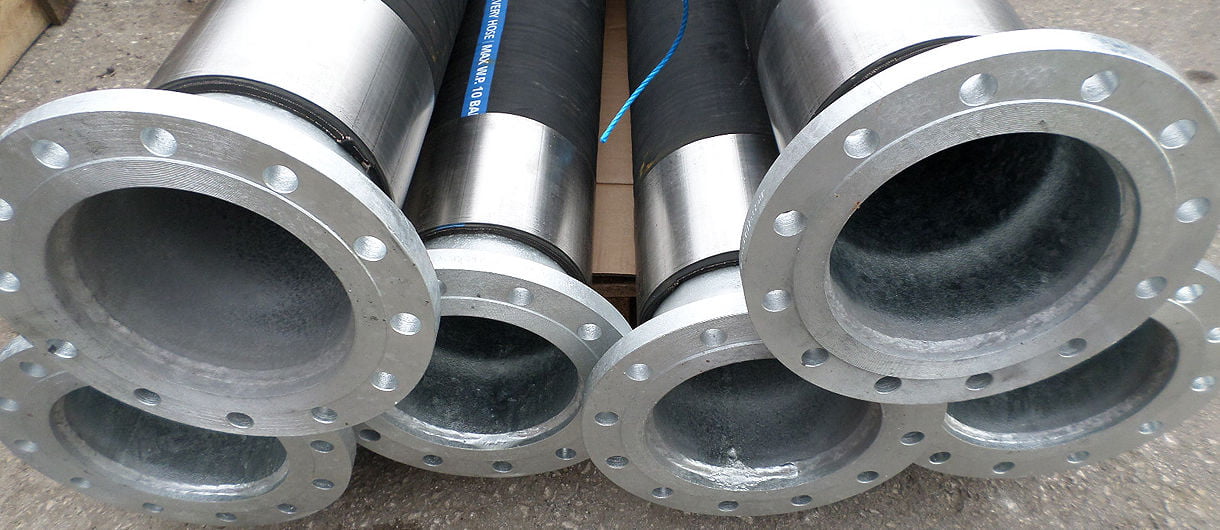

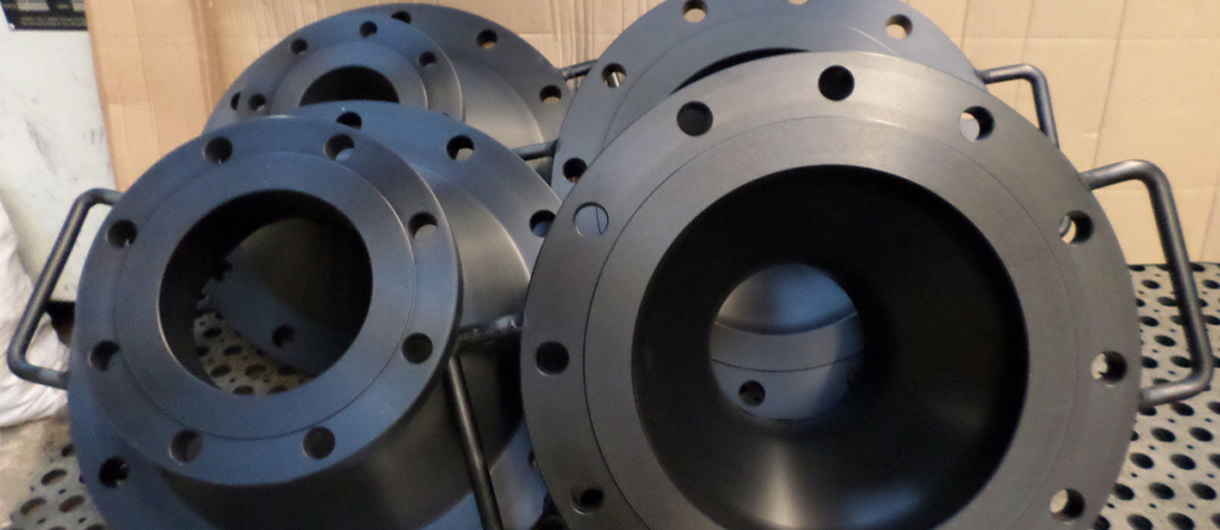

Weld Neck Flanged Hose Tails with Serrated Interlock Ferrules

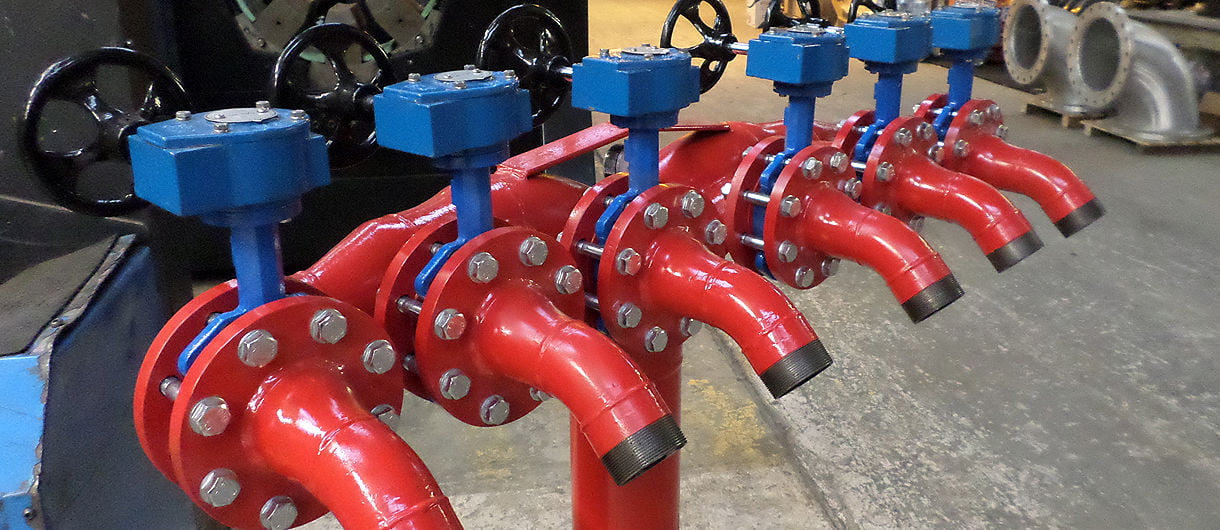

Fixed and Swivel Hose Tails in Carbon Steel

Swivel Hose Tails in Carbon Steel

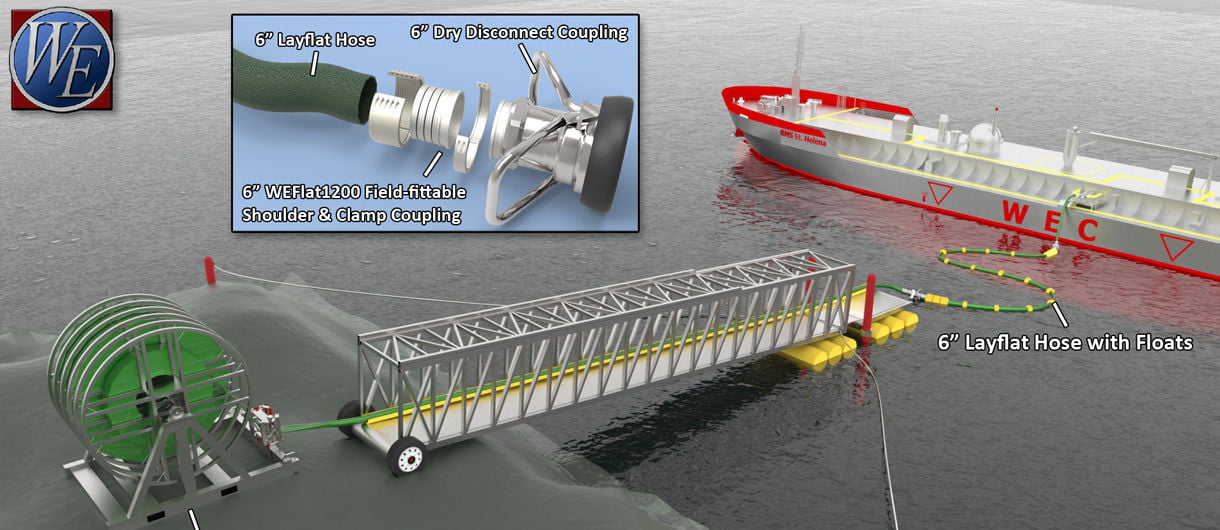

6″ Flanged ASA150 Hose tails in Carbon Steel, Stainless Steel & H.A. Alloy

High quality serrated weld tails